In today’s fast-paced manufacturing environments, efficiency is key to maintaining a competitive edge. One essential component in optimizing production lines, especially in packaging and material handling industries, is the carton accumulation system. For businesses looking to streamline operations, minimize downtime, and ensure smooth product flow, investing in a robust carton accumulation system can make all the difference. Here, we’ll dive into the importance of carton accumulation and why Dillin’s engineered systems are the go-to solution for businesses looking to enhance their automation processes.

What Is a Carton Accumulation System?

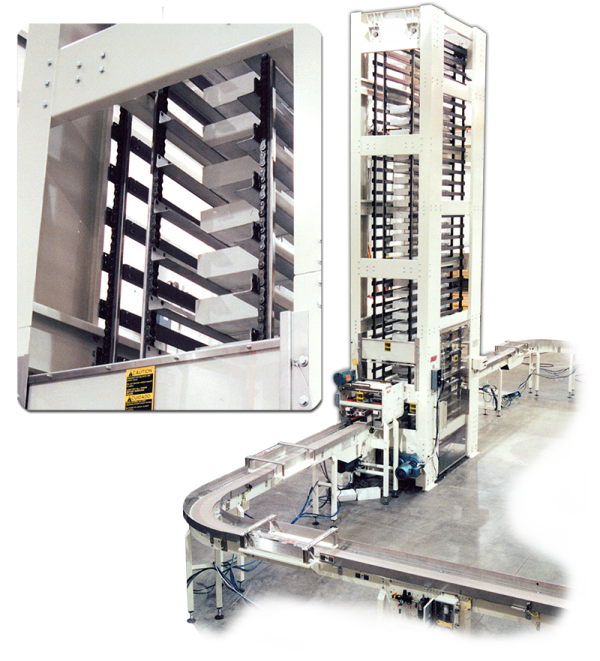

A carton accumulation system is designed to manage and organize cartons or boxes during various stages of a production line. These systems temporarily hold cartons before they move on to the next phase in the manufacturing process, ensuring that the upstream and downstream operations continue running smoothly without interruptions.

Carton accumulation systems serve multiple purposes:

- Buffering: They prevent backups or delays by holding excess cartons during slower processing stages.

- Flow Management: By spacing out or accumulating cartons, these systems maintain a consistent flow of materials, essential for preventing bottlenecks.

- Integration: They work seamlessly with existing conveyor systems, ensuring products are handled efficiently from start to finish.

Why Carton Accumulation Matters

Proper carton accumulation is crucial for businesses dealing with high volumes of packaged goods. Whether you’re in the food and beverage, pharmaceutical, or consumer goods industry, maintaining an uninterrupted flow is essential to meeting production quotas and avoiding costly delays.

Here’s why investing in a high-quality carton accumulation system is critical:

- Maximizing Throughput: Accumulation systems allow manufacturers to maximize the number of cartons processed in a given time. By reducing bottlenecks, they ensure that each phase of production moves at the optimal speed.

- Reduced Downtime: When an unexpected issue arises further down the line, an accumulation system allows the rest of the production process to continue operating. This buffer time prevents sudden stops that can disrupt the entire line.

- Improved Flexibility: A well-engineered carton accumulation system can adapt to varying production speeds and carton sizes, ensuring consistent performance regardless of the specific production needs.

- Cost Savings: Efficient material handling reduces labor costs, as fewer workers are needed to manually adjust or intervene with production. Over time, this can significantly improve the bottom line.

Dillin’s Engineered Carton Accumulation Solutions

At Dillin, we understand that every production line is unique. That’s why our carton accumulation systems are designed to be fully customizable to meet the specific needs of your business. With decades of experience in the field, we have developed systems that not only maximize efficiency but also integrate seamlessly with other automation technologies.

Our solutions are built to handle a wide variety of packaging materials, ensuring reliable performance across industries. Whether you need a solution for round container sortation, lid sortation, or any other custom-engineered material handling challenge, Dillin has the expertise to deliver.

Features of Dillin Carton Accumulation Systems

- Advanced Control Systems: Our carton accumulation systems are equipped with intelligent control systems that ensure smooth and reliable operation. By utilizing state-of-the-art automation technology, we guarantee precision and efficiency at every stage of the process.

- Modular Design: Flexibility is at the core of Dillin’s approach. Our systems are modular, allowing for easy scalability and future upgrades. This means that as your business grows, your accumulation system can grow with it, adapting to new production demands.

- Seamless Integration: Dillin’s carton accumulation systems integrate effortlessly with other conveyor systems such as table top chain conveyors, mat top conveyors, and custom-engineered solutions. Whether you’re installing a new system or upgrading an existing line, our solutions are built for seamless integration and minimal downtime.

- High Durability: Built from high-quality materials, our systems are designed for long-term use, even in the most demanding industrial environments. Dillin’s systems are designed to handle both lightweight and heavy cartons with ease, ensuring consistent performance over time.

Why Choose Dillin?

At Dillin, we pride ourselves on being industry leaders in automation systems and engineered solutions. Our carton accumulation systems are designed with precision, reliability, and efficiency in mind. We work closely with our clients to ensure each system is customized to their specific production needs, providing a solution that enhances overall performance and reduces operational costs.

With a commitment to innovation and customer satisfaction, Dillin has built a reputation for delivering high-quality, reliable systems that streamline operations and boost productivity. Our expertise extends to industries such as food processing, pharmaceuticals, consumer goods, and more, making us a trusted partner for businesses looking to upgrade their material handling processes.

Conclusion

A well-engineered carton accumulation system can significantly improve your production line’s efficiency, reduce downtime, and ultimately save costs. Whether you’re dealing with high-volume packaging operations or looking for ways to improve flow management, Dillin’s accumulation systems offer the perfect solution.

Looking to optimize your production line with a carton accumulation system? Contact Dillin today to learn how our customized solutions can help take your business to the next level.